The gear mesh tester of OSAKA SEIMITSU mainly uses the "standard gear" and the "product gear" for mesh test, measuring the change of the distance between the shaft centers of two gears as the measurement accuracy error, and is used to test the accuracy of a single tooth The error and the accuracy error of the whole tooth are suitable for the grade judgment of JIS/ISO/AGMA/DIN/JGMA and other quality standards.

Thermogravimetric analyzer is an instrument that uses thermogravimetric method to detect the relationship between temperature and mass change of a substance. When there is sublimation, vaporization, decomposition of gas or loss of crystal water during the heating process, the quality of the measured object will change, and the thermogravimetric curve will decrease. By analyzing the thermogravimetric curve, it is mainly used for the testing of polymers (thermoplastics, thermosetting resins, elastomers, adhesives and composite materials) and metal powder metallurgy materials.

MITUTOYO SUEFTEST SJ-41D surface roughness measurement system is used to test the surface roughness of gears. The test results are JIS (JISB0601-2001, JIS-B0601-1994, JISB0601-1982), VDA, ISO-199 and ANSI. In addition to the calculation results, it can also display the combined calculation results and evaluation profile, load curve and amplitude distribution curve.

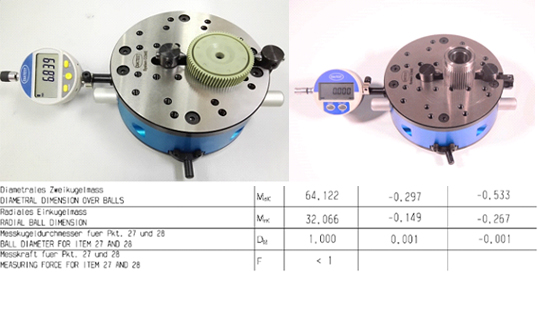

The German DIATEST DIA-COME internal and external tooth (diameter) measuring table can quickly switch between the measurement modes of the internal and external diameters of the internal and external teeth, and measure it by adjusting the test force comparison method.